Filling technology solutions

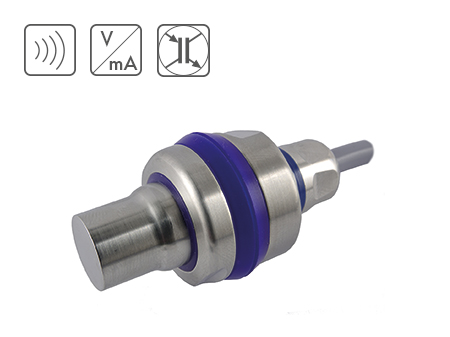

Ultrasonic sensors provide precise measurements of fill levels and positions. This accuracy is essential for the optimal dosing of liquids and bulk solids, avoiding overfilling or underfilling. Ultrasonic sensors can be used in different types of containers and with different liquid or powdery substances, regardless of their color, transparency or viscosity.

The sensor uses the measured time of flight to calculate the distance to the surface of the substance. Since the geometry of the container is known, the fill level of the liquid or other substances can be calculated precisely.

As ultrasonic sensors are contactless, there is no risk of contaminating the product. This is particularly important in sectors such as the food and pharmaceutical industries, where hygiene plays a critical role.

Typical applications

- Continuous level measurement

- Monitoring of minimum and maximum fill levels

- Level monitoring

- Overflow monitoring

Matching products

Your consultation with our experts

Convinced? We will be happy to advise you according to your requirements and support you right from the start - from the development of your individual sensor solution to implementation and further services.